Quality Control in Jewelry Manufacturing

OUYA adheres to stringent standards throughout the entire jewelry production process. We have established a comprehensive quality control system, and rigorous testing is carried out at every stage to ensure that every piece of jewelry meets the high quality standards and the stringent requirements of high-end brands in Europe, the United States, and other regions.

Raw Material Testing

Supplier Risk Management

We only work with ethically, socially, and environmentally responsible suppliers. All raw metals and gemstones require test reports and sourcing contracts as part of future finished products to ensure they are harmless and ethically sourced.

Leading Stainless Steel Jewelry Manufacturer and Supplier

OUYA is no ordinary custom jewelry company. We are dedicated to producing the highest quality products while remaining committed to environmental sustainability. We strive to exceed our customers’ expectations and provide products that best suit their needs and styles. We believe that quality comes from selecting the finest materials and employing the most efficient manufacturing processes.

Adhering to Rigid Quality Standards

All our jewelry at wholesale prices possesses the highest quality standards. This is our guarantee to all our clients.

Raw material inspection

All raw materials used in jewelry production are strictly inspected before entering the manufacturing process

4-Step Quality Check

After the jewelry is completed, we will conduct a comprehensive quality inspection on each piece

Specialized Quality Inspectors

Our quality control auditors receive thorough training and years of experience.

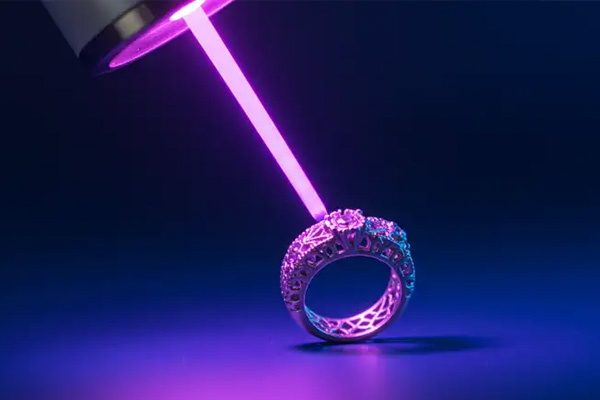

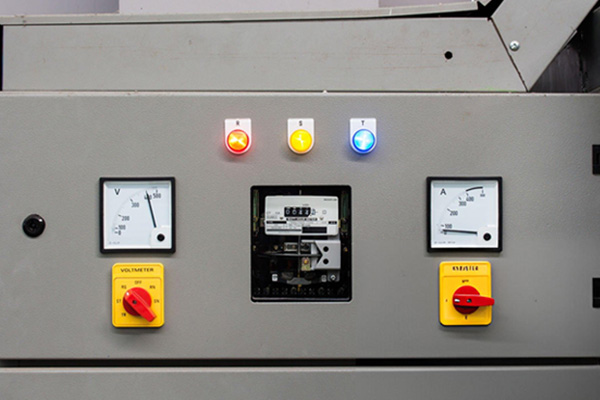

Professional testing equipment

We are equipped with a full set of professional testing equipment in-house to accurately monitor every detail

100% Every Piece Inspection

We’re confident the final product meets your standards with every piece inspected.

Beyond Industry Standards

Meeting or even raising the standards mean they’re sure to pass global requirements.

Our Commitment to Jewelry Excellence

Each link is carefully inspected to ensure that each work exceeds industry standards and brings lasting value to customers.

- 8 way to plating quality inspection processes

1. Salt spray test

To verify its excellent corrosion resistance, the jewelry must be continuously sprayed in a neutral (pH 6.5-7.2) salt solution for 24 hours.

2. Friction test

Apply a certain pressure to the sample to perform friction test. Only jewelry with intact coating can pass the test.

3. Artificial sweat test

Soak the jewelry in artificial sweat at 40°C, pH 5.5, for several hours and check for discoloration and corrosion.

4. Sulfur dioxide test

Apply sulfur dioxide to the sample surface and observe the number of points where the paste changes color after a period of time to evaluate the porosity.

5. Vibration wear test

Helps determine the degree of wear and tear each piece of jewelry can withstand, performing friction tests to simulate the wear and tear of long-term wear

6. UV testing

UV aging test: 24 hours of accelerated UV exposure to test surface anti-yellowing, anti-fading and durability

7. Thermal shock testing

Heat the jewelry in a high-temperature furnace for 15-30 minutes and observe whether the coating bubbles or peels off.

8. Hardness test

This test uses a 1H to 5H pencil and applies 1 kg of pressure to test the hardness of jewelry coatings.

- Finished product inspection

1. External coating inspection

We check the consistency of the electroplating process to ensure it adheres perfectly to the substrate, has a uniform color, and meets the required thickness.

2. Overall shape

Check whether the overall shape of the jewelry is consistent with the design or sample, and whether there is any deformation

3. Performance Check

Compare your finished jewelry piece to your design files to ensure every part is the way you wanted it

4. Appearance inspection

Whether the polishing is bright and uniform, without pitting, sand holes, scratches, file marks and other defects

5. Metal edges

Check whether the finished product has clear and smooth lines, no burrs or scratches

6. Structural connections

Are the welding points firm, smooth and without marks? Is the chain flexible and knot-free? Is the buckle open smoothly and safely?

7. Stone setting inspection

Check that all gemstones are firmly set, the micro-set stones are neatly positioned, the channel setting is flat, and there are no edge seams.

8. Dimensions and weight

Verify that the final product meets the required size, color and shape and achieve consistent results

Ask Us Anything

Do you offer discounts for bulk orders?

Yes, we offer discounts for bulk orders. Please contact us with the details of your order to receive a quote.

Why is wholesale jewelry cheaper?

Wholesalers usually offer diamonds at much lower prices than what you would pay at a branded jewelry store because overheads like distribution and marketing costs are already eliminated. This means that you are buying diamonds from the same place, at the same price, as the fancy diamond jewelry retailers do.

Can I get a sample before placing a large order?

Yes, we offer customization and personalization services. Please contact us with your specific requirements.

What is your minimum order quantity?

Whether you are a small business or an established brand, we offer flexible solutions to meet your needs.